Mitsubishi -A2ACPU-P21 Programmable Logic Controller

Price 17200 INR/ Piece

Mitsubishi -A2ACPU-P21 Programmable Logic Controller Specification

- Input

- Digital 16 points (expandable depending on I/O modules)

- IP Rating

- IP20

- Operating Temperature

- 0 ~ 55C

- Resolution

- Bit level for digital I/O

- Sensors Specification

- Compatible with standard industrial digital/analog sensors (via expansion modules)

- Components

- CPU Unit, backplane connector, LED status indicators

- Processor Speed

- Up to 16 MHz (depends on version)

- Power Source

- External supply required

- Power Supply

- External

- Usage

- Industrial Automation Control Systems

- Response Time

- 1ms basic instruction speed (typical)

- Interface

- RS-232C, Expansion bus, Programming port

- Features

- High reliability, modular design, expandability, real-time operation, diagnostic LEDs

- Display Type

- LED status indicators

- Output

- Digital 16 points (expandable depending on I/O modules)

- Product Type

- CPU Unit for A Series PLC

- Application

- Manufacturing, Process Control, Machine Tool Automation

- Rated Voltage

- 24V DC / 100-240V AC (varies by model and configuration)

- Supply Voltage

- 24V DC or 100-240V AC

- Size

- Standard Mitsubishi A Series CPU size

- Dimension (L*W*H)

- 115mm x 50mm x 155mm (approximate)

- Function

- Programmable Logic Controller (PLC)

- Color

- Black with grey/brown accents

- Weight

- Approx. 0.5 kg

- Capacity

- Program capacity up to 14k steps (depending on memory)

- Thickness

- Standard PLC chassis thickness

- Current Rating

- 0.5A (varies as per input module)

- Frequency

- 50/60 Hz

Mitsubishi -A2ACPU-P21 Programmable Logic Controller Trade Information

- Minimum Order Quantity

- 01 , , Piece

- Supply Ability

- 100 Pieces Per Week

- Delivery Time

- 4-5 Days

About Mitsubishi -A2ACPU-P21 Programmable Logic Controller

Versatile Usage for Advanced Automation

The Mitsubishi - A2ACPU-P21 PLC serves both general and specific automation needs in manufacturing and process control. Designed for industrial environments, its robust expandability supports machine tool automation and tailored control applications. Whether for general use in workflow management or for specialized machinery integration, this PLC's configurable inputs/outputs and real-time operation deliver precise, uninterrupted control, adapting seamlessly to varying automation scenarios.

Domestic Market Excellence & Shipping Details

Premier in India's main domestic market for automation, the Mitsubishi - A2ACPU-P21 PLC features a competitive rate and reasonable outlay for shipped goods. Products are dispatched promptly from major FOB ports for optimal reach. All units are certified to international standards, ensuring quality and compliance. Rated highly for reliability and performance, this PLC meets industry demand with consistent excellence in documented shipments and verified certifications.

FAQ's of Mitsubishi -A2ACPU-P21 Programmable Logic Controller:

Q: How can the Mitsubishi - A2ACPU-P21 PLC be expanded for specialized automation tasks?

A: The controller supports expansion through digital, analog, communication, and special function modules, enabling tailored solutions for complex automation requirements in various industries.Q: What communication protocols are supported by the A2ACPU-P21 PLC for integration?

A: It supports MELSECNET/10, MELSECNET/HS, and CC-Link (via modules), with RS-232C and expansion bus interfaces, ensuring wide compatibility for industrial networks.Q: Where is the Mitsubishi -A2ACPU-P21 most commonly used in India?

A: It is widely utilized in the manufacturing sector, process control environments, and machine tool automation, especially in industrial automation control systems nationwide.Q: When should battery-backed RAM or EPROM/EEPROM be used for data retention?

A: Battery-backed RAM is standard for user program memory retention, while EPROM/EEPROM is recommended for additional, permanent storage, especially in critical or long-term automation deployments.Q: What are the main benefits of using this PLC in a production environment?

A: Key benefits include high reliability, modular design for easy expansion, real-time operation, diagnostic LED indicators, and robust memory retention, contributing to minimized downtime and optimized automation.Q: How is protective grounding achieved for safe operation of the PLC?

A: Protective earthing must be implemented as per installation guidelines to ensure safe operation, safeguard equipment, and meet compliance requirements within industrial setups.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Mitsubishi Programmable Logic Controller Category

fx1n-40mr-001-MITSUBISHI PROGRAMMABLE LOGIC CONTROLLER

Price 98000 INR / Thousand

Minimum Order Quantity : 1 Number

Rated Voltage : 24V DC

Function : Programmable logic control for automation applications

Weight : Approx. 0.5 Kg

6SL32 46-OA A22-IFA 0-siemens programmable logic controller

Price 28000 INR / Piece

Minimum Order Quantity : 1 Piece

Warranty : 12 months

Rated Voltage : 380480 Volt (V)

Function : SINAMICS G120X Rated power: 110 kW At 110% 60s, 100% 240 s Radio interference suppression filter for category C2 380480 V 3 AC +10/20% 4763 Hz Ambient

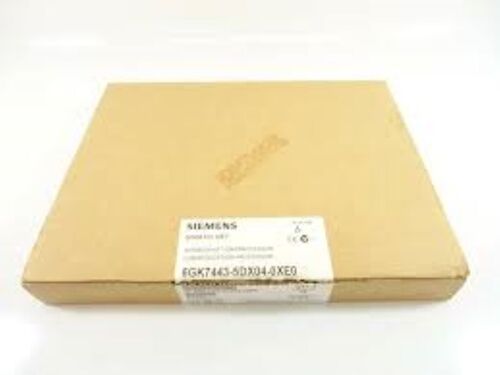

6GK7443-5DX04-0XE0 -siemens programmable logic controller

Price 45000 INR / Thousand

Minimum Order Quantity : 1 Piece

Warranty : 12 months

Rated Voltage : 5 V dc Volt (V)

Function : functions that support the secure operation of plants, solutions, machines, equipment and/or networks. They are important components in a ...

Weight : 0,802 Kg Kilograms (kg)

6AV6 644-OA BO1-2AXOsiemens programmable logic controller

Price 277000 INR / Thousand

Minimum Order Quantity : 1 Piece

Warranty : 12 months

Rated Voltage : 24 V Volt (V)

Function : 6AV66440AB012AX0. Product Description, The new part, as of 01.01.2015, is blocked for delivery. Spare part can continue to be purchased as required, but ...

Weight : 5,780 Kg Kilograms (kg)

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry